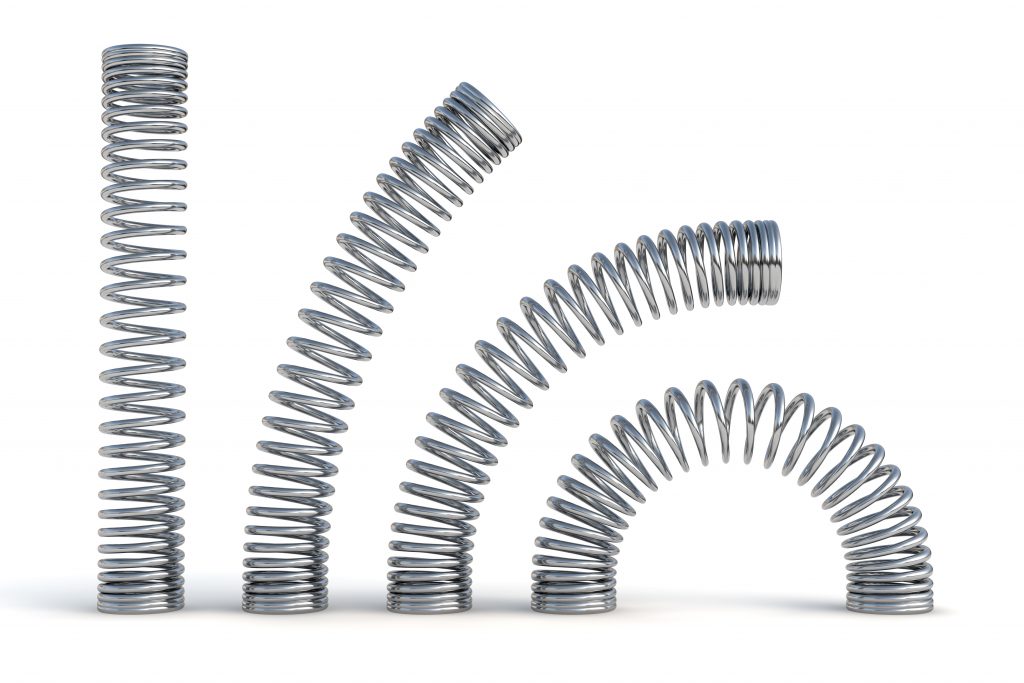

Within the manufacturing industry, there are numerous designs and forms of spring that are used for different projects. Each spring, pressing or wire form has a specific purpose, each working differently to maximise their potential.

Tension springs and compression springs look similar therefore it is understandable to confuse the two, however they are actually designed to do very different things. Here at European Springs were going to reveal how springs that look so similar can be so different.

What Are Tension Springs?

The design difference between compression springs and tension springs is that the latter usually have a loop or a hook attached at either end these are for attachment purposes. Tension springs, sometimes known as extension springs, can be found in garage doors, but a trampoline is a better example of this type of spring in action.

The primary function of this type of spring is to allow an outside force to create tension then use energy to pull components back together. Tension springs are usually wound very tightly, and this spring is in a state of rest when it is coiled closely together. If the coils of a tension spring are damaged it will not be able to return to its original state of tension.

Tension springs can be used in a wide range of industry sectors, including rail, agriculture, oil and gas and aerospace. As tension springs can come in a diverse array of sizes, they can be used for many applications. Here are the most common uses of this type of spring:

- Trampolines

- Automotive interior and exterior

- Garage doors

- Farm equipment

- Pliers

- Medical devices such as stretchers and surgical lights

What Are Compression Springs?

Although compression springs are also a form of coil spring, they are designed to work differently to tension springs. Compression springs are often manufactured from a much larger gauge wire and are not wound as tightly as their tension counterparts.

The compression spring is the most common type of spring and can be found in many different products and machines such as; mattresses, pogo sticks, watches, and mobile phones. The compression spring is at rest when it appears to be in an extended position and is designed to resist a compressive force.

There are many different types of compression spring. Here are some examples of this type of spring:

- Conical

- Hourglass

- Barrel-shaped

- Torsional

- Magazine

Compression springs are another spring that are hugely popular and can be used within several different industries. You may not be aware, but we use these springs every day, even in some places you may not have known. Here are some of the most common components which use this type of spring:

- Valves

- Locking doors

- Railways

- Cars

- Electrical switches

- Large stamping presses

- Ballpoint pens

What Are Their Main Differences?

Tension springs are mainly used to hold two components together whereas compression springs are used to keep components from meeting. Both springs have a coil spring design for strength and elasticity however they are used in entirely different ways.

Compression and tension springs work in opposite ways however they are both exceptional inventions that are a necessary to many different products. They are two magnificent examples of the coil spring.

If you require any more information in regards to spring technology, do not hesitate to get in touch with our compression spring manufacturers here at European Springs by phoning +44 (0) 208 663 1800 or email [email protected].